Why Choose Us

Factory

We insist on the management purpose that "taking the human resources as the dominant factor, reputation if first, users are uppermost".

Sustainable Success

We apply co-creation methodologies. The resulting ownership is a sound basis for sustainable success.

Exceptional Customer Service

Our promise is to guarantee the perfect quality and service.

Rich Experience

We only focused on the development and production of transmission rubber belt equipments.

Related Product

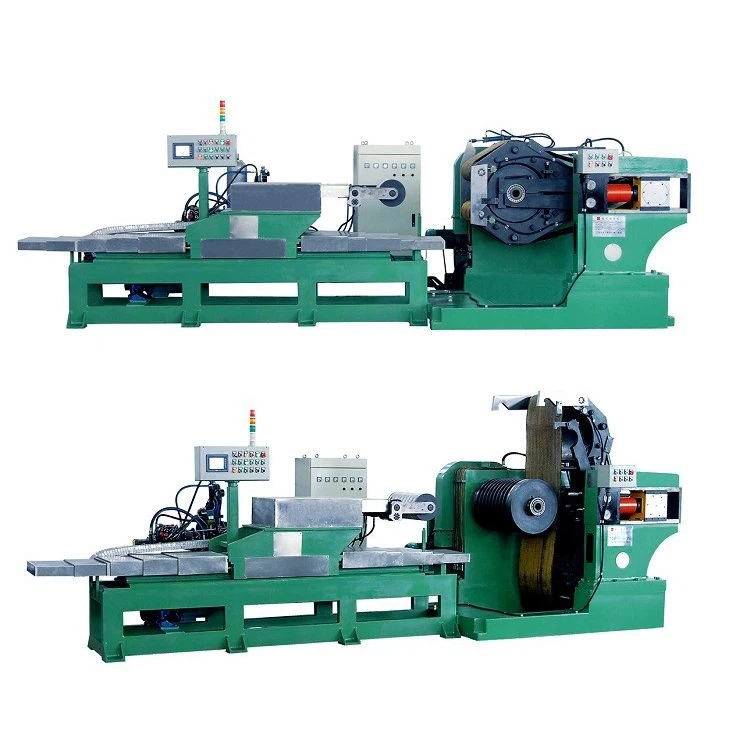

This machine is used for after V belt building, Strip Billet intermittent vulcanizing. the machine motor is press type single cylinder single acting piston jaw type structure, around a fixed mechanism and elongation institutions, Equipped with electric telescopic and electric device, after building the Strip Billet of groove wheel according to the trough plate type line order detailed arrangement. this machine is consist of fixed mechanism, motor, elongation institutions,piping system andelectrical equipment.

This machine is main to used for V belt core outside fabric wrapped building. It is controlled by PLC, automatic tensioning, let off fabric, wrapping and cutting processes.

The equipment is mainly used for curing various models of agricultural machinery V-belt, a large V-belt and banded V-belt continuously.

The equipment is mainly used for cured belt stabilizing and cooling process It is convenient for the belt to set faster, improve the vulcanization efficiency, quality and product appearance.

The equipment is used for v belt timing belt poly belt rubber sleeve to vulcanizing building.

The equipment is used for v-belt timing belt poly belt rectangle length measurement.

The equipment is used for V-belt winding, rubberizing, and cutting. Each drum as meet specifications within a certain range of V-belt molding.

1) Used in timing belt cord fabric sleeve gum dipping and dry process.

2) Angle floating can adjustable doctor blade, ensure uniform gum dipping.

What is Fabric Dipping Machine?

A Fabric Dipping Machine is a piece of equipment used in the textile industry for the process of dyeing fabrics. This machine facilitates the uniform application of dyes or finishes to textiles by immersing them into a vat containing the dye solution. The primary goal of using a Fabric Dipping Machine is to achieve consistent coloration, finish, or treatment across the entire fabric, regardless of its size, shape, or thickness.

The working principle and composition of the Fabric Dipping Machine

Working principle

Fabric Dipping Machine is a machine that applies materials to substrates. It is usually used to attach materials to various substrates, such as paper, fiberboard, metal plate, glass, rubber, etc. Its working principle is to put the substrate that needs to be impregnated from the coating liquid into the machine through a dipping tank or roller, and then press out the excess liquid through rollers or other pressure equipment to make the surface of the substrate smooth and uniform, and then dry it through The drying and curing processes complete the entire dip coating process.

Structural composition

The Fabric Dipping Machine mainly consists of the following components:

1. Dip tank: Used to hold paint and impregnate the substrate.

2. Calender roller: After impregnation, the substrate passes through a calender roller to press off excess paint and make the surface smooth.

3. Heating system: Controls the temperature of the coating area to achieve better coating results.

4. Drying system: Send the impregnated substrate into the oven, solidify the coating by heating, and dry it within a certain period of time.

5. Transfer system: Transfer the impregnated, calendered and dried substrate to the next process.

Features of Fabric Dipping Machine

High production efficiency: The Fabric Dipping Machine adopts the method of dipping with glue roller or dipping tank, which can continuously, efficiently and uniformly glue the yarn or fabric, which improves production efficiency.

Energy saving and environmental protection: The vertical glue dipping machine adopts an intermittent glue coating method, which only starts the motor when glue needs to be applied, and completely stops the motor operation when it is not working, thus achieving the purpose of energy saving and environmental protection.

Intelligent control system: The vertical dipping machine adopts an intelligent control system, which can monitor the operating status of the equipment in real time, realize automatic control and automatic adjustment, and greatly reduce the difficulty of operation and work intensity.

Easy to operate: The operation panel of the vertical glue dipping machine is simple and clear. The operator can start, stop, adjust the glue amount and other operations of the equipment by touching the screen, eliminating the need for tedious manual adjustments.

Stable structure: The vertical glue dipping machine has a reasonable structural design, uses a heavy-duty base, a sturdy support frame, and good equipment stability, ensuring the glue coating effect and the service life of the equipment.

Safety Operating Procedures Of Fabric Dipping Machine

1. The installation location of the Fabric Dipping Machine must be in a ventilated, dry, bright, clean, non-corrosive gas and dust-proof environment.

2. When installing, ensure that the machine is stable and stable, the four legs should be fixed, and the supporting surface should be smooth and flat without tilt or shaking.

3. Pay attention to power supply and grounding protection during installation to ensure correct wiring and reliable grounding to prevent electric shock accidents.

1. Before using the Fabric Dipping Machine, you should be familiar with the structure, performance, operation and maintenance methods of the dipping machine to ensure safe operation.

2. Appropriate work clothes and protective equipment should be worn during operation. Loose clothing is prohibited to prevent accidental involvement and other dangers.

3. Before starting, you must check whether the machine components are installed and connected, and check whether the electrical equipment is operating normally. After starting, you should observe whether there are any abnormalities. If there are any abnormalities, you should stop the machine immediately for troubleshooting.

4. Operation should be carried out in accordance with the instructions, and parameters, feeding and exhaust should not be changed at will.

5. It is prohibited to use unauthorized or untested materials in processing operations to avoid safety accidents.

6. The Fabric Dipping Machine is prohibited from being overloaded, and operators cannot leave their posts. Regular inspections of the machine are required to detect problems in a timely manner to prevent safety accidents due to negligence.

1. Check whether the Fabric Dipping Machine is in good condition after each use, clean the residues in all parts, and ensure that the machine is well ventilated and that there are no impurities inside.

2. Regularly inspect and maintain the machine, such as replacing parts, lubricating oil, etc., to avoid malfunction of the dipping machine.

3. Regularly inspect and maintain the dipping machine to ensure the performance and safety of the dipping machine.

4. Follow the operating procedures and do not disassemble the machine without authorization, let alone modify the structure of the dipping machine to prevent accidental dangers.

A Fabric Dipping Machine is a device used to dip fiber materials into resin. During the carbon fiber manufacturing process, a dipping machine immerses the fiber material (usually carbon fiber fabric or yarn) into a specific resin slurry so that it can fully penetrate and cover the fiber material. This allows the fiber material to bond firmly with the resin, creating a strong and durable carbon fiber product.

The role of the Fabric Dipping Machine is not only to immerse fiber materials into resin, but also to control the thickness and uniformity of the dipping material. By adjusting the parameters of the dipping machine, such as dipping speed, dipping time and dipping pressure, manufacturers can achieve precise control over the performance of carbon fiber products. This customized production method allows carbon fiber products to meet the needs of different application fields.

The Fabric Dipping Machine can also introduce other additives such as pigments, fire retardants and reinforcements into the carbon fiber manufacturing process. These additives can enhance the functionality and aesthetics of carbon fiber products, making them more suitable for various application scenarios. For example, in the aerospace field, carbon fiber products need to be high-temperature resistant and fire-resistant; while in the automotive manufacturing field, carbon fiber products need to be lightweight and high-strength. The flexibility of the dipping machine makes these requirements possible.

The role of the Fabric Dipping Machine in carbon fiber manufacturing cannot be ignored. It not only provides an efficient and precise dipping process, but also provides manufacturers with more innovative possibilities. By continuously optimizing and improving the technology of the dipping machine, the quality and performance of carbon fiber products have also been significantly improved.

In the increasingly competitive carbon fiber manufacturing market, having an advanced dipping machine will become the key for companies to stand out. Fabric Dipping Machine It can help companies improve production efficiency, reduce costs, and produce higher-quality carbon fiber products. Therefore, if you plan to enter the carbon fiber manufacturing industry, don't overlook the importance of a Fabric Dipping Machine.

Production principle of Fabric Dipping Machine

The glue Fabric Dipping Machine is to immerse the object into a liquid medium coated with glue. Through various technical means, the glue can penetrate into the surface and interior of the object to form a variety of products that are strong, wear-resistant, fold-resistant, waterproof, antioxidant and heat-insulating. Function. Dip processing is commonly used in the processing of rubber, plastics, fabrics, metals, wood and other materials, and is widely used in automobiles, electrical appliances, communications, machinery, building materials and other industries.

The Fabric Dipping Machine consists of a frame, heating system, coating system, auxiliary system, control system and other parts. During processing, the glue liquid maintains a certain temperature and pressure in the glue dipping tank, is fed into the coating roller, and is evenly coated on the material surface driven by the high-speed rotating coating roller. The material is then heat treated through an oven or other heat source to cure the glue.

Fabric Dipping Machine are widely used in various dipping processing fields and can process and coat different materials, including high-temperature polymerization, coating, roller, brushing, spraying, dipping and other coating methods. The advantage of the dipping machine lies in its high efficiency, energy saving, environmental protection and other characteristics, and it can quickly and accurately complete coating quality control.

Precautions For Daily Operation Of Fabric Dipping Machine

1. Before starting the equipment, it is necessary to ensure that the gas source pressure is stable. Recommended pressure: 0.6MPa~0.8MPa.

2. After using the Fabric Dipping Machine every day, the raised pressure roller needs to be lowered. If the roller does not come down, after turning off the air compressor, the roller will automatically fall down when there is no air. This is very unsafe. Yes, it will damage the roller.

3. After the Fabric Dipping Machine is stopped every day, the power switch of the equipment control cabinet must be turned off, otherwise it will be very unsafe. The consequences of not doing this are: when the main power switch is turned on directly When encountering industrial power supply fluctuations and unstable voltage and current, a large instantaneous pulse current will be generated, which will cause fatal damage to the low-voltage electrical appliances of the Fabric Dipping Machine.

4. Equipment operation and shutdown maintenance require two or more people: one person is responsible for control and one person is responsible for observing the operating status of the equipment. The equipment must be equipped with a machine director, Dedicated personnel are responsible for the operation and daily maintenance of the equipment.

5. When the equipment is used, the unwinding tension should be adjusted accordingly according to the actual conditions of the raw materials (gram weight and tensile deformation).

6. When the cloth storage device is used, the number of cloth threading guide rollers can be adjusted according to the actual situation. The greater the number of cloth threading guide rollers, the greater the friction of the cloth and the greater the traction force. The traction device will The torque setting will be increased accordingly. When the cloth storage device and the unwinding device are used together, the unwinding tension is adjusted accordingly according to the number of cloth threading guide rollers.

7. Before adjusting the pressure roller gap, you must first measure the thickness of the fabric, and then make corresponding adjustments according to the actual resin conditions and process conditions; do not exceed the safety gap to avoid damaging the pressure roller. Specific operation method: first use a micrometer to measure the thickness of the fabric, then use a feeler gauge to measure the gap between both ends of the pressure roller and the middle position, and adjust the gap adjustment device at both ends of the pressure roller to achieve Appropriate gap value, keep the gap at both ends consistent.

8. After each use of the Fabric Dipping Machine, the resin on the rollers and scraper plates must be cleaned promptly to prevent the resin from curing and damaging the rollers.

9. The temperature of the cooling system can be adjusted according to the ambient temperature and process requirements, and good use effects have been achieved.

10. When using the film unwinding device, adjust the air pressure according to the diameter of the PE film roll and the tensile strength of the PE film to achieve better unwinding tension; at the same time, adjust the curvature of the flattening roller. to adjust the flattening effect.

11. Automatic correction system: When the prepreg fabric is wound normally and there is no deviation, the automatic correction system will not operate; when the prepreg fabric is deflected, the automatic correction system will automatically Make corrective adjustments.

Certifications

Our Factory

We insist on the management purpose that "taking the human resources as the dominant factor, reputation if first, users are uppermost". Our promise is to guarantee the perfect quality and service.

FAQ

Hot Tags: fabric dipping machine, China, suppliers, manufacturers, factory, made in China, belt wrapping system for commercial v belts, type v belt machine for commercial production, type v belt manufacturing machine, type v belt wrapping unit for industry, raw edge belt premiere, belt wrapping equipment