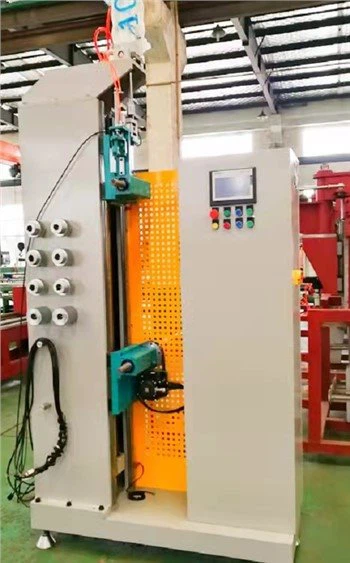

Agricultural V-belt Machine

Xia Hua founded in 1990 more than 30 years construction history. We only focused on the development and production of transmission rubber belt equipments. The company's main products include wrapped type V- belt machine, classic V-belt machine, agricultural V-belt machine, cutting type V- belt machine, v-belt moulds, etc.

-

Curing Press MachineThis machine is used for after V belt building, Strip Billet intermittent vulcanizing. the machineAdd to Inquiry

-

Stabilizing Cooling Machinehe equipment is mainly used for cured belt stabilizing and cooling process It is convenient for theAdd to Inquiry

-

V-belt VulcanizerThe equipment is used for v belt timing belt poly belt rubber sleeve to vulcanizing building.Add to Inquiry

-

Fabric Dipping MachineA Fabric Dipping Machine is a piece of equipment used in the textile industry for the process ofAdd to Inquiry

-

Length Measure MachineThe equipment is used for v-belt timing belt poly belt rectangle length measurement.Add to Inquiry

-

Automatic Wrapping MachineThe machine is used for automatically belts fabric wrapping process.Add to Inquiry

-

Rotocure MachineThe equipment is mainly used for curing various models of agricultural machinery V-belt, a largeAdd to Inquiry

-

Expandable DrumThe equipment is used for V-belt winding, rubberizing, and cutting. Each drum as meetAdd to Inquiry

-

Fabric Dipping Machine1) Used in timing belt cord fabric sleeve gum dipping and dry process.. 2) Angle floating canAdd to Inquiry

- Tel: +86-579-88988787

- Fax: +86-579-88988757

- Kevin.g@xiahua-machinery.com

- Add: 12-Qiulin Road, Light Industry Section, Lanxi City, Zhengjiang Province, P.R. China

Why choose us?

Sales market

Region: Europe, America, Middle East, Southeast Asia, Iran, India, Japan, South Korea, Russia, etc.

High quality

The company has long been committed to providing high product quality and perfect support services to ensure the stable operation of users' equipment and products.

Professional team

The company has a group of senior construction personnel with rich experience, which can well solve all kinds of equipment faults and strongly ensure the needs of customers.

Types of Agricultural V-Belt Machine

The Agricultural V-Belt Machine Produced By Our Company Mainly Includes the Following Types:

Automatic wrapping machine

An automatic wrapping machine, often referred to as a stretch wrapper, is a piece of packaging equipment that automatically wraps pallets or loads with a plastic stretch film, providing stability and protection by securely holding the products together during storage and transportation; essentially, it eliminates the need for manual wrapping by applying the film consistently around the entire load.

Rotocure machine

Rotocure curing press, also be called drums type curing press, is used for the continuous production of rubber sheets, rubber fabrics, coated fabrics, lightweight rubber conveyor belts, etc. It is an alternative to the traditional vulcanizing method, and is particularly suitable for large-scale mass production due to the continuity of its process. And the equipment can be adjusted by temperature, pressure, speed and other parameters to meet the production needs of different rubber products.

Benefits of Agricultural V-Belt Machine

1.Automatic wrapping machine

Improved efficiency: Stretch wrapping machines automate the process of wrapping palletized loads, allowing businesses to package goods more quickly and efficiently compared to manual wrapping methods. With automated stretch wrapping, companies can handle higher volumes of products in less time, leading to increased productivity and throughput.

Cost savings: While the initial investment in a stretch wrapping machine may be significant, the long-term cost savings can be substantial. By reducing the need for manual labor and minimizing film waste through precise tension control, businesses can lower their packaging costs over time. Additionally, automated stretch wrapping can help prevent product damage during transit, reducing the likelihood of costly returns or replacements.

Enhanced load stability: Stretch wrapping machines apply stretch film evenly and securely around palletized loads, providing greater stability and protection during transportation and storage. The tight seal created by the stretch film helps prevent shifting, tipping, and damage to the packaged goods, reducing the risk of losses and ensuring that products reach their destination in optimal condition.

Versatility and customization: Stretch wrapping machines come in various configurations and can accommodate different types of loads, shapes, and sizes. They offer flexibility in adjusting wrapping parameters such as film tension, overlap, and number of revolutions to meet the specific requirements of each packaged item. Whether packaging lightweight or heavy-duty loads, stretch wrapping machines can be tailored to suit a wide range of applications and industries.

2.Rotocure machine

High production efficiency: The equipment is designed for high-speed mass production, with a high degree of automation, reducing the manual intervention of manpower, and running efficiently and stably.

Continuous operation: Its continuity minimizes the variation of the vulcanization process, which can efficiently realize the mass production of rubber sheets.

Uniform vulcanization: Under the precise control of temperature and pressure, the equipment can ensure final product quality and performance consistency.

Wide range of applications: The equipment can process different types of rubber compounds and manufacture various rubber products.

Energy-saving and environmentally friendly: The equipment adopts an energy-saving design, which helps reduce the overall energy consumption during the vulcanization process.

- Productivity: 10000

- Place of Origin: China

- Supply Ability: 1000

- Payment Type: T/T,L/C,Western

Packaging and Shipping

Certifications

FAQ

As one of the leading agricultural v-belt machine manufacturers and suppliers in China, we warmly welcome you to buy high-grade agricultural v-belt machine made in China here from our factory. All our machines are with high quality and competitive price.

v belt wrapping system for factories, industrial v belt sealing press, v belt making machine for workshops